Minnesota Power pilots Cirrus to new heights of energy efficiency

Dec 19, 2016

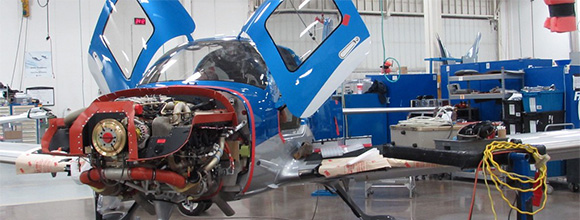

Innovation and continuous improvement have made Cirrus Aircraft a leader in general aviation. Its iconic high-performance SR22 series is the best selling aircraft in its class, and the highly anticipated Vision Jet promises similar success with almost 600 units on order prior to FAA certification in late October 2016.

Cirrus Aircraft’s headquarters and manufacturing plant in Duluth, Minn., reflect that spirit of innovation. Buildings are packed with cutting-edge equipment and systems that keep the company’s energy usage, demand and costs from going sky high. This includes a new 70,000-square-foot paint and detail facility opening in January 2017.

The new building’s innovative lighting design, HVAC (heating, ventilation and air conditioning) system, and other high performance features draw upon years of collaboration with Minnesota Power’s Power of One® Business Conservation Improvement Program. They help the company save energy, while ensuring a safe, healthy and comfortable work environment.

Aircraft manufacturing is energy intensive by nature. The high tech production and finishing processes demand intense and sustained heat, a controlled climate, excellent lighting and industrial equipment that require robust electricity. Any opportunity to save energy or improve efficiency goes straight to the bottom line.

Cirrus Aircraft Facilities Director Alan Jusczak is a strong advocate for energy efficiency. Since joining the company in 2002, he has worked closely with CIP staff and consultants to complete a long list of energy-saving improvements that have qualified for utility rebates due to their electric demand and kilowatt hour savings. The relationship has enabled numerous projects that otherwise might not been completed.

“I’ve been here 14 years and I know we have received more than $400,000 in rebates from Minnesota Power that we have reinvested back into other improvements,” Jusczak said. “We roll those funds into future energy-saving projects like LED lights, heat recovery systems or process changes.”

One project currently underway is a conversion to LED lighting in the main manufacturing building. Minnesota Power consultants brought in numerous samples to determine which LED lights would best meet the rigorous lighting demands of the aircraft manufacturer.

“We tried many different LED bulbs, fixtures and brands over a period of a year-and-a-half to two years,” Jusczak said. “Through that process of elimination, we chose a fixture with a full 10-year warranty that not only saves energy but reduces maintenance costs because we don’t have to continually change out ballasts and bulbs.”

Lighting upgrades began in the detail area, so employees could ensure perfection before completed aircraft were seen by customers. The bright, white LED lights have performed so well, they are being expanded to the wing bond area.

“Now that employees have seen the LED lighting there, they want it in other areas,” Jusczak said. “The new paint building is designed completely with LED fixtures … even the parking lot lights.”

Another energy-efficiency measure that has proved to be successful in the main plant and now is being replicated in the body shop of the new building is a dropped ceiling that reduces the number of dust collectors needed to control indoor air quality during paint prep. Lowering the ceiling and reducing the space also has lowered the plant’s heat load and air conditioning requirements—saving both electricity and natural gas energy.

Additional HVAC improvements are underway, as well. Cirrus recently replaced eight rooftop air conditioning units with more efficient models and added economizers to several others. A recommissioning project is planned to review all units and identify ways to improve energy savings. The Minnesota Power CIP group helped define the scope and goals of that project.

A study also is in the works to analyze and optimize compressed air systems in the plant. Air leaks can be a significant source of wasted energy for manufacturers whose processes depend on compressed air. Cirrus Aircraft completed a similar study in 2009 and reduced electric demand by 42 kilowatts and usage by about 211,000 kilowatt hours. The new paint building will have an energy-efficient variable speed drive air compressor and two standard compressors with a high-flow oil/water separator to maintain pressure and conserve energy.

Staying ahead of the curve is important to Jusczak. He and another Cirrus facility manager completed Building Operator Certification training sponsored by Minnesota Power in 2006, and they maintain that certification with continual projects. Cirrus personnel also attend Minnesota Power-sponsored classes and seminars to stay current on technologies like lighting, energy-saving controls and variable speed drive motors.

“In a company the size of Cirrus Aircraft, it is important to have a person like Alan (Jusczak) who believes in energy conservation and trusts that we can be of assistance,” said Minnesota Power commercial energy consultant Tanuj Gulati, of Energy Insight Inc. “If he has a project or a question about energy efficiency, he knows who to call for good advice.”

“We have a long-term relationship with Minnesota Power,” said Jusczak, noting that every year Minnesota Power provides a detailed progress report to assist Cirrus with planning and budgeting. “It is a tool I can use to show senior management the projects completed, the electric demand and kilowatt hours saved, and the rebates received. They see the value of reinvesting those savings in additional projects.”